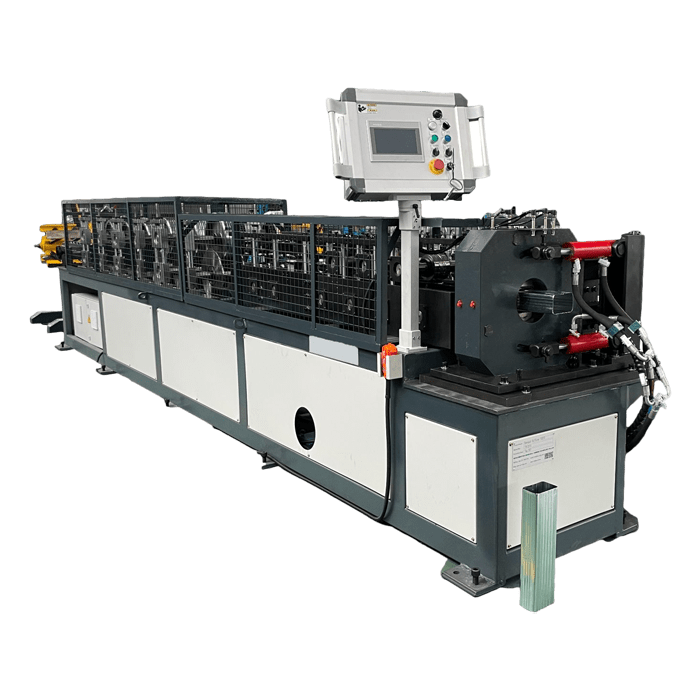

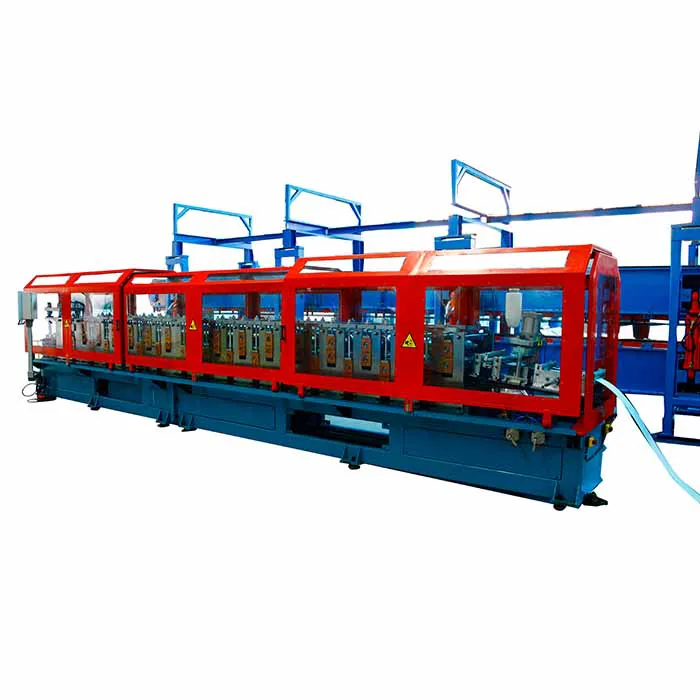

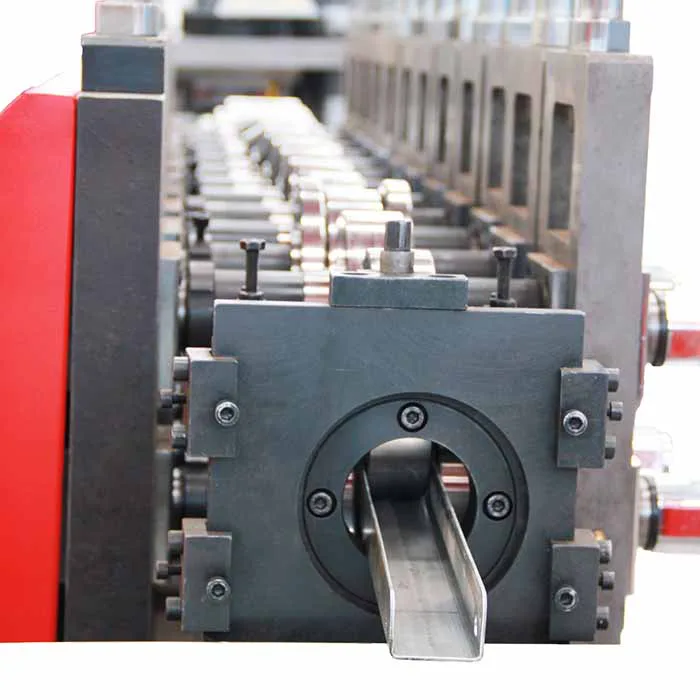

Roll Forming Machine

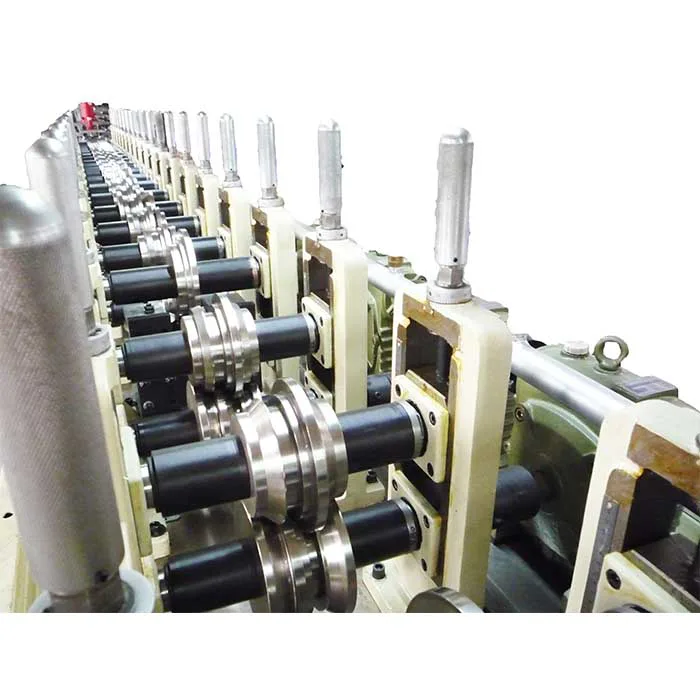

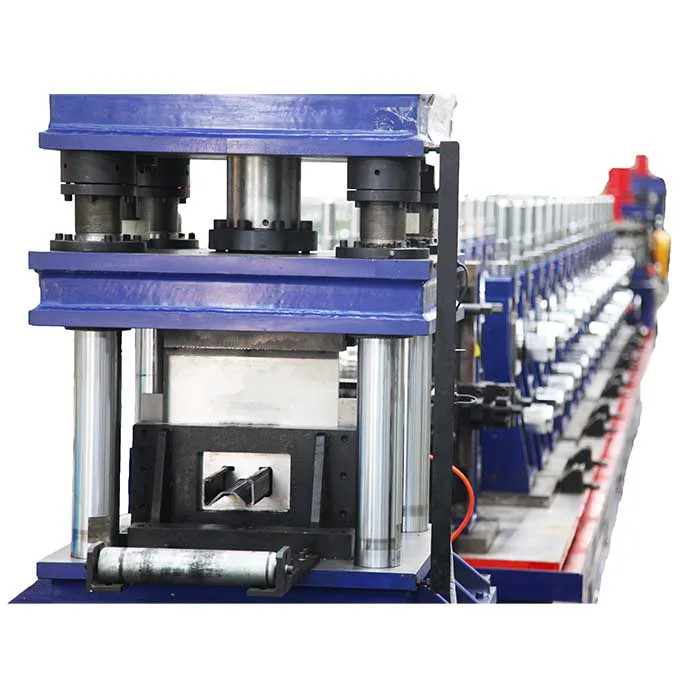

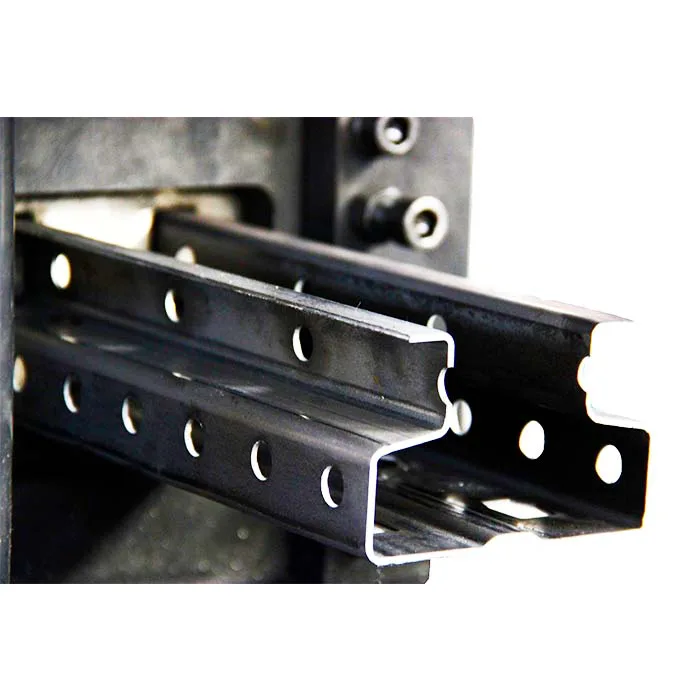

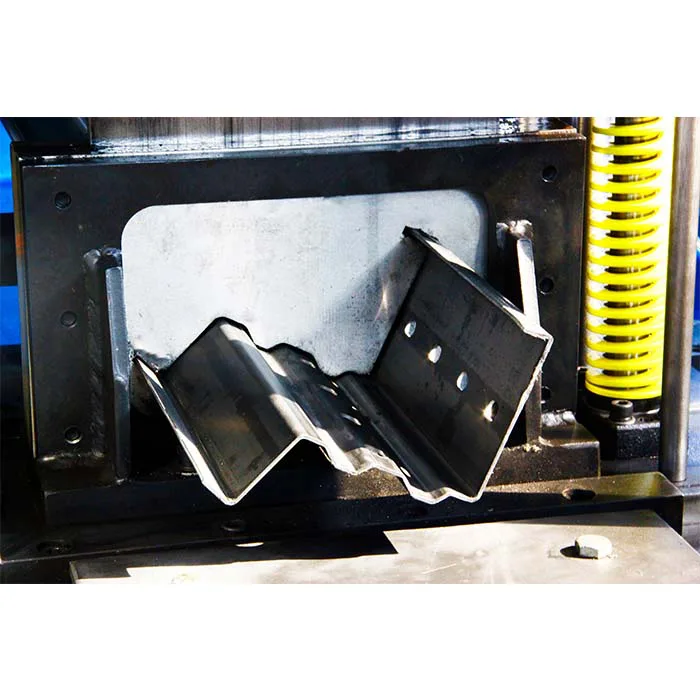

Roll forming machines make special configurations from long strips of metal, usually from coiled steel. In most applications, the required section profile of the part is specially designed so that the machine bends the metal if necessary. In addition to roller forming, these machines perform a number of metalworking tasks, including cutting materials and punching rollers. The components of the roll forming machine include roll forming parts, PLC, computer control system, hydraulic pump station system, and automatic cutting system. Roll shutter machines work in a continuous cycle in most cases. The material is fed into the machine where it continuously makes its way through the stages of each operation, ending with the completion of a final product. Manufacturing companies can manage high-quality processes as the automation of roll forming machines removes the scope for human error and improves the overall quality of production.