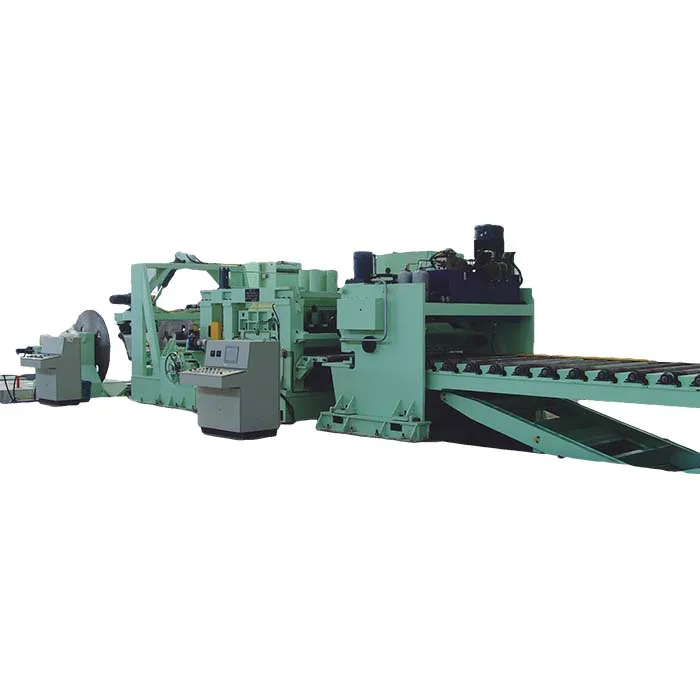

Steel Coil Cut to Length Line

Steel Coil Cut to Length Line

Cutting line for cutting flat rectangular blanks from main coils. For widths of up to 3000 mm, thicknesses of up to 25 mm and speeds of up to 150 m/min.

The lines can be supplied with start-stop shears, flying shears, rotating shears or continuous direct feed. Air cushion, bomb-door type, electromagnetic or vacuum stackers. High-precision levellers of four, five and six heights, computer controlled. Edge trimming may be incorporated..

Totally computer-controlled with diagnosis, automatic coil feed and quality control.

For carbon steel, exposed and non exposed material, stainless steel, pre-painted steel, aluminium and other metals.

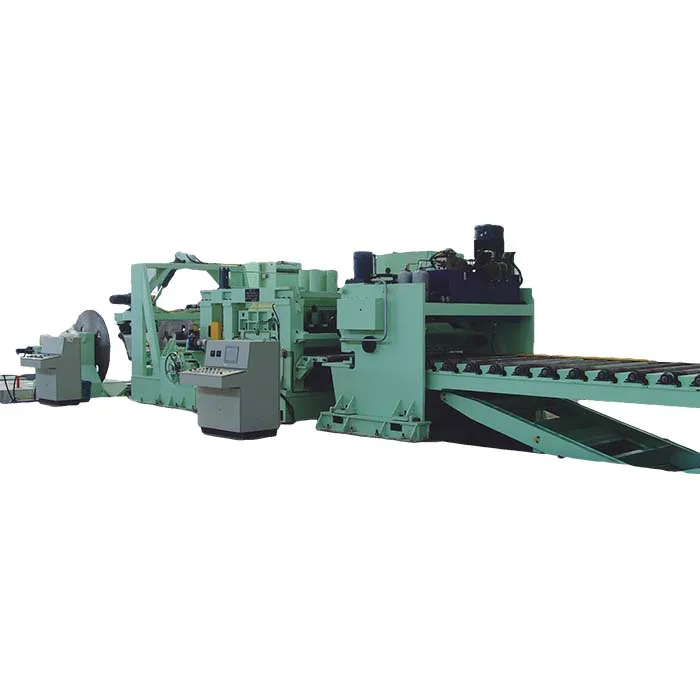

Cutting line for cutting flat rectangular blanks from main coils. For widths of up to 3000 mm, thicknesses of up to 25 mm and speeds of up to 150 m/min.

The lines can be supplied with start-stop shears, flying shears, rotating shears or continuous direct feed. Air cushion, bomb-door type, electromagnetic or vacuum stackers. High-precision levellers of four, five and six heights, computer controlled. Edge trimming may be incorporated..

Totally computer-controlled with diagnosis, automatic coil feed and quality control.

For carbon steel, exposed and non exposed material, stainless steel, pre-painted steel, aluminium and other metals.

Customized machine productivity.

Customized machine fabrication cost.

Customized machine production accuracy.

Customized machine configuration.

Customized machine footprint.

| MODEL | THICKNESS (mm) | WIDTH (mm) | INNER DIAMETER (mm) | OUTTER DIAMETER (mm) | COIL WEIGHT (T) | TRANSVERSE CUTTING SCOPE (mm) |

LENGTH PRECISION (mm) | DIAGONAL PRECISION (mm) |

PLANENESS (mm/?O) | SPEED (m/min) |

MAIN POWER (kw) | FLOOR SPACE (m) |

| 2.0×500 | 0.2-2.0 | 200-500 | Φ508 | ≤Φ1200 | ≤6 | 300-1500 | ≤±0.5 | ≤±0.8 | ≤1.5 | 15~50 | ~75 | 16×4 |

| 2.0×650 | 0.2-2.0 | 200-650 | Φ508 | ≤Φ1200 | ≤6 | 300-1500 | ≤±0.5 | ≤±0.8 | ≤1.5 | 15~50 | ~75 | 16×4 |

| 2.0×1300 | 0.3-2.0 | 500-1300 | Φ508/610 | ≤Φ1500 | ≤15 | 500-3500 | ≤±0.5 | ≤±0.8 | ≤1.5 | ≤50 | ~95 | 22×7 |

| 2.0×1600 | 0.3-2.0 | 500-1600 | Φ508/610 | ≤Φ1600 | ≤15 | 500-4000 | ≤±0.5 | ≤±0.8 | ≤1.5 | ≤60 | ~122 | 22.5×8 |

| 2.6×1850 | 0.5-2.6 | 400-1850 | Φ508/610 | ≤Φ1500 | ≤20 | 400-4000 | ≤±0.5 | ≤±1.0 | ≤1.0 | 8~80 | ~180 | 25×9 |

| 3.0×1600 | 0.3-3.0 | 500-1600 | Φ508 | ≤Φ1500 | ≤20 | 500-4000 | ≤±0.5 | ≤±1.0 | ≤1.5 | ≤40 | ~90 | 23×8 |

| 4.0×1600 | 0.6-4.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤20 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤50 | ~100 | 30×8 |

| 6.0×1600 | 1.0-6.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤30 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤30 | ~155 | 35×8 |

| 8.0×1600 | 2.0-8.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤20 | ~180 | 25×8 |

| 9.0×1600 | 2.0-9.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤20 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤20 | ~170 | 25×8.5 |

| 10×1600 | 2.0-10 | 800-1600 | Φ508-Φ760 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤30 | ~240 | 42×8 |

| 12×2000 | 3.0-12 | 1000-2000 | Φ508-Φ760 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤16 | ~255 | 50×10 |

| 12×1800 | 3.0-12 | 800-1800 | Φ508-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±1.0 | ≤±1.5 | ≤2.0 | ≤16 | ~255 | 50×10 |

| 16×2000 | 4.0-16 | 1000-2000 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | ≤±3.0 | ≤2.0 | ≤12 | ~275 | 50×10.5 |

| 20×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | ≤±3.0 | ≤3.0 | 10~16 | ~220 | 29×9.6 |

| 22×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | ≤±3.0 | ≤3.0 | 10~16 | ~220 | 29×9.6 |

| 25×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | ≤±3.0 | ≤3.0 | 10~16 | ~220 | 30×11 |