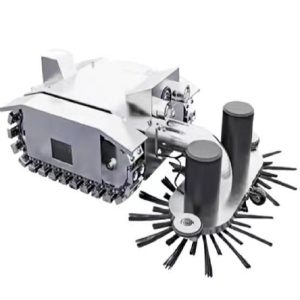

Spiral Duct Forming Machine

Spiral Duct Forming Machine

The spiral duct forming machine is professional for straight spiral and corrugated duct fabrication. Loading with raw steel coil, the machine adopts a motor driving the feeding rolls to feed the material strip into the forming rolls. By adjustments on the forming rolls, the pipe can be adjusted on diameters easily from 80mm to 1600mm. After the forming to a certain length, the machine adopts saw cutting or plasma cutting to cut off the pipe and feed outside. All movements on the machine are controlled by PLC and step motor. It is working also combines a round pipe elbow-making machine, a seam welding machine, an angle iron round rolling machine, and three roller bending machines to make any size of round duct easily.

The spiral duct forming machine is professional for straight spiral and corrugated duct fabrication. Loading with raw steel coil, the machine adopts a motor driving the feeding rolls to feed the material strip into the forming rolls. By adjustments on the forming rolls, the pipe can be adjusted on diameters easily from 80mm to 1600mm. After the forming to a certain length, the machine adopts saw cutting or plasma cutting to cut off the pipe and feed outside. All movements on the machine are controlled by PLC and step motor. It is working also combines a round pipe elbow-making machine, a seam welding machine, an angle iron round rolling machine, and three roller bending machines to make any size of round duct easily.

This machine is a special machine for spiral tube forming machine.

The material rack adjusts the feeding direction to adapt to the different needs of the spiral tube forming.

Leveling rollers level and shape the male and female sides that require the joint.

Can be suitable for helix forming of different materials and thicknesses.

Spiral tubes of different diameters can be formed by changing belt dies of different diameters.

Determine the length of the spiral tube to be formed by positioning the photoelectric switch.

Optional saw blade or plasma cut to length the spiral tube duct.

The cutting method is follow-up cutting to ensure the cutting surface is neat.

Pneumatic cylinder controls the up and down movement of the saw blade for cutting.

Pick-up table supports formed and cut of helix tube.

| Model | TF-1500 |

| Material | GI, AL, SS steel sheet |

| Diameter Range | 80~1500 mm |

| Tube Length | 125~6000 mm |

| Strip Width | 137 mm |

| lock Seam | Outside tube, inside on request |

| galvanization | 0.4~1.2 mm |

| Stainless Steel | 0.4~0.8 mm |

| Aluminum | 0.4~1.2 mm |

| Max. Strip Speed | 38 m/min |

| Dimensions | 2650×1550×2000 mm |

| Weight | 2200 kg |

| Control System | PLC automatic control |

| Power Supply | 5.5 kw |

| Power Supply of Cutting Motor | 4 kw |

| Working Pressure | 0.5~0.7 Mpa |

| Thickness Match Diameter | 0.4 80-300 mm |

| 0.5 80-500 mm | |

| 0.6 100-700 mm | |

| 0.8 150-1000 mm | |

| 1.0 300-1200 mm | |

| 1.2 400-1500 mm |