Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

Pittsburgh Lock Forming Machine

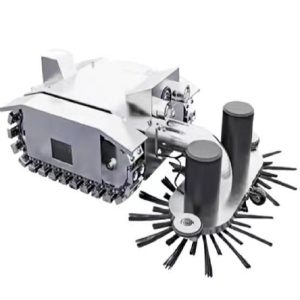

Pittsburgh Lock Former with stations is a multi-functional machine for varying uses in the HVAC ducting industry. It is designed for the formation of different types of seams, which are used in the manufacture of rectangular and round ducts, chimneys, gutters. The rolls are made from the highest quality case-hardened special steel and can be easily changed.

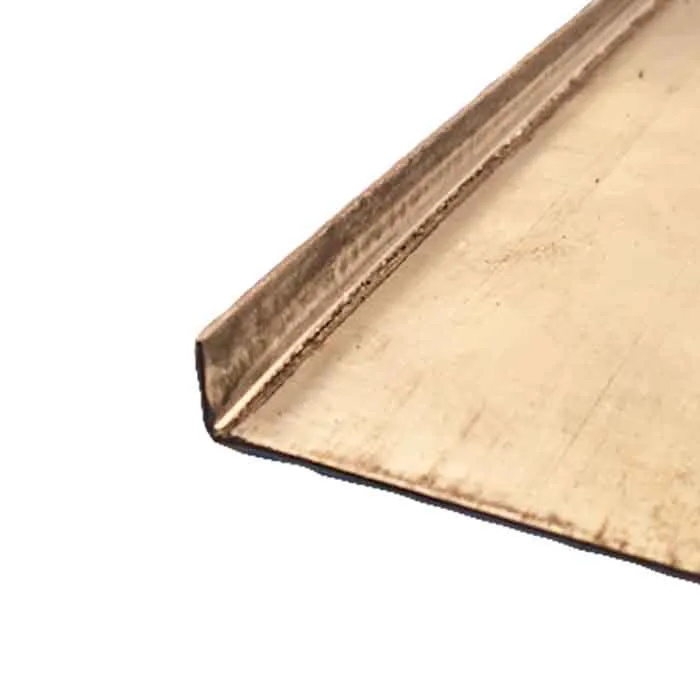

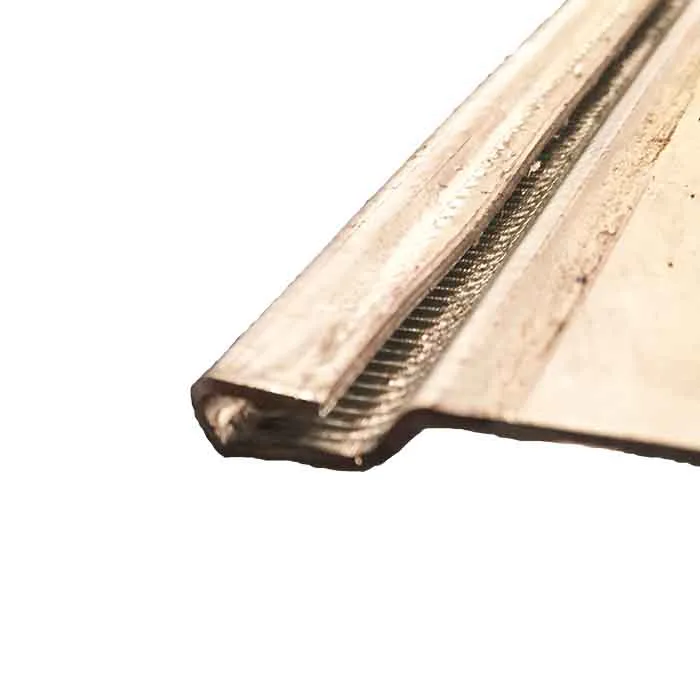

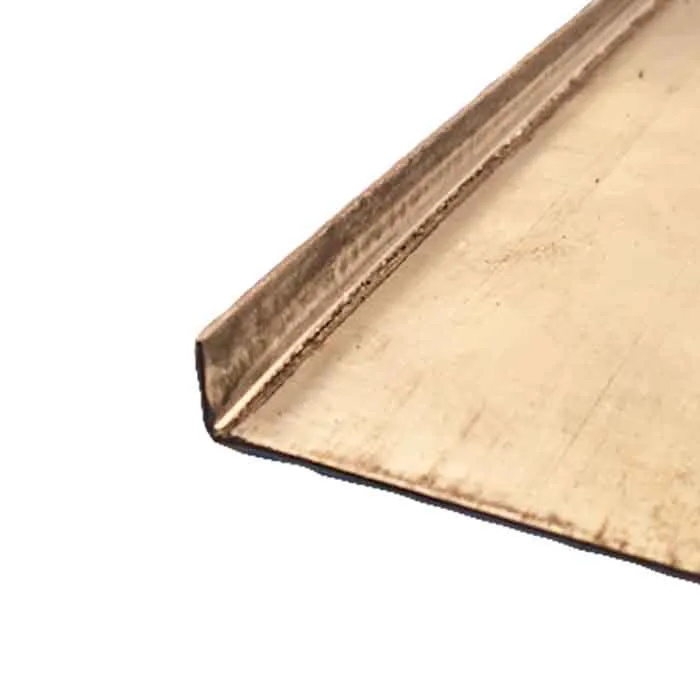

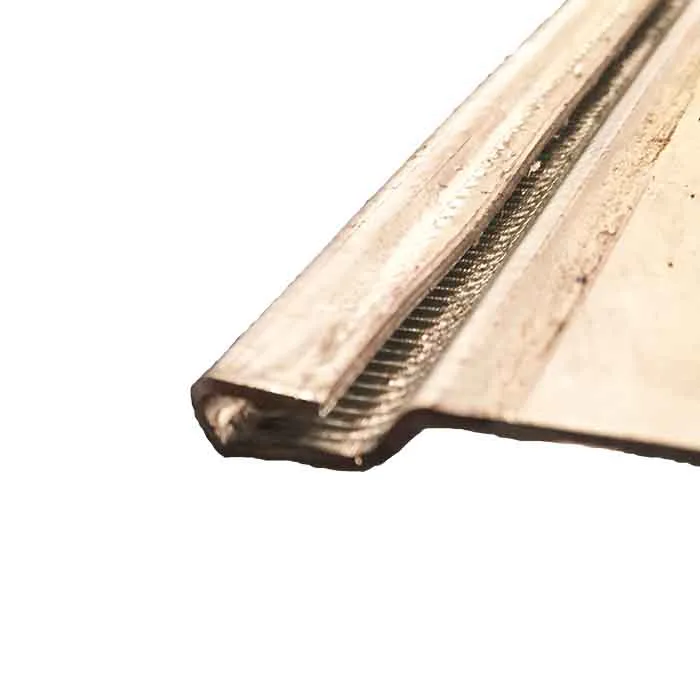

LC-12DR , this 7 forming station Pittsburgh Lock Former with 6 forming positions, Pittsburgh Lock, Double Seam (ACME), Right Angle Flange, Drive Cleat with slitter, standing seam and Power Flanger.

LC-12M, this 8 forming station Pittsburgh Lock Former with 4 forming positions, Pittsburgh Lock, Double Seam (ACME), “S” Cleat and Drive Cleat.

Standing Seam and T connection are optional.

LC-12E, this 7 forming station Pittsburgh Lock Former with 2 forming positions, Female Button Lock and Male Button Lock.

Pittsburgh Lock Former with stations is a multi-functional machine for varying uses in the HVAC ducting industry. It is designed for the formation of different types of seams, which are used in the manufacture of rectangular and round ducts, chimneys, gutters. The rolls are made from the highest quality case-hardened special steel and can be easily changed.

LC-12DR , this 7 forming station Pittsburgh Lock Former with 6 forming positions, Pittsburgh Lock, Double Seam (ACME), Right Angle Flange, Drive Cleat with slitter, standing seam and Power Flanger.

LC-12M, this 8 forming station Pittsburgh Lock Former with 4 forming positions, Pittsburgh Lock, Double Seam (ACME), “S” Cleat and Drive Cleat.

Standing Seam and T connection are optional.

LC-12E, this 7 forming station Pittsburgh Lock Former with 2 forming positions, Female Button Lock and Male Button Lock.

Multifuntion for total Pittsburgh lock male and female, C cleat, drive cleat, Z cleat and Arc right angle roll forming.

Roller made of high quality alloy die steel.

Needle roller bearings are suitable for high-intensity work.

Durable wear-resistant transmission gear.

Two-way switch controls feeding and discharging.

High quality power motor.

High-strength machine support frame.

Universal movable casters for easy transfer of machine.

Customized request voltage.

Reliable machine service life mor than 8 years.

| Model | LC-12DR |

| Working Material | Galvanized sheet |

| No Adjustment for Material | 0.5~1.2mm |

| Working Station | 7sets |

| Roller Material | GCr15 |

| Roller Shaft Material | Thermal refined 45# |

| Transmission | V-belt |

| Control | Normal electric control |

| Working Speed | 9m/min |

| Power Capacity | 1.5kw |

| Dimension | 1050*580*1050mm |

| (LxWxH) | |

| Weight | 230kg |