Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

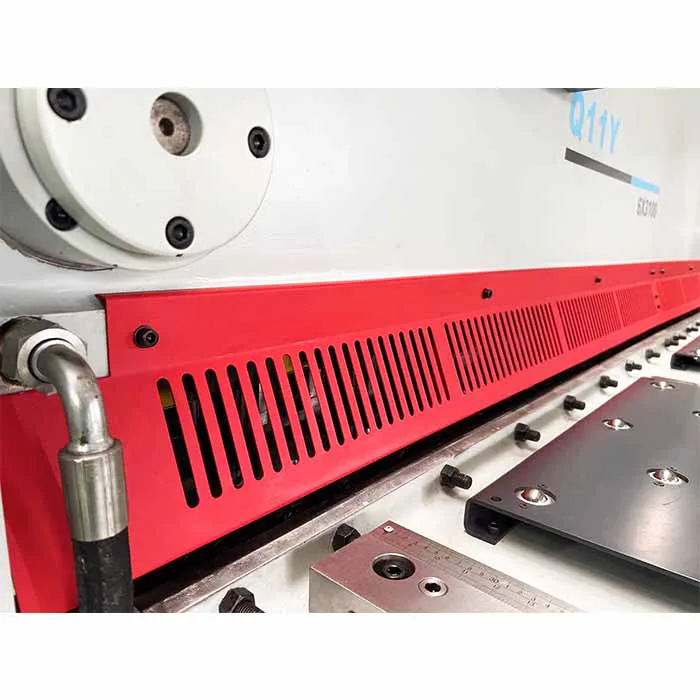

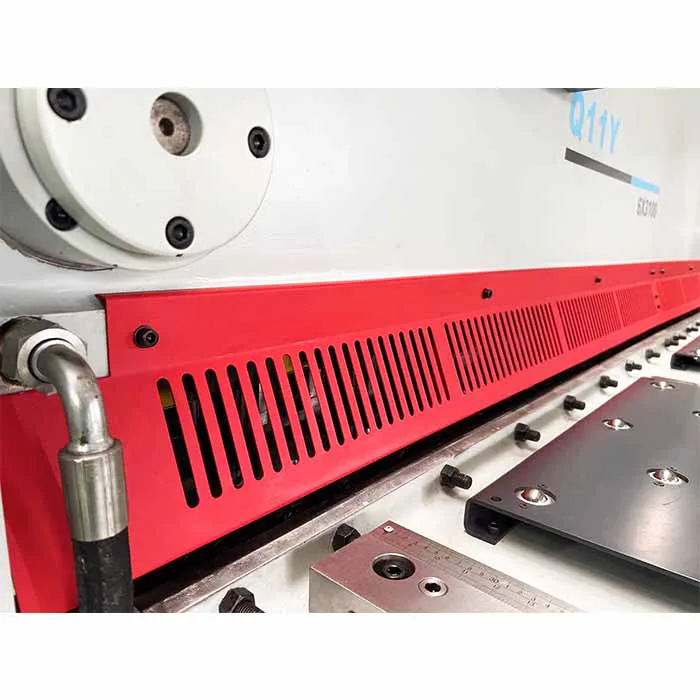

The upper cutting beam moves at an angle and along an arc in relation to the bottom, which provides an accurate cut on any metal thickness. Sturdy constructions, the frames and beams prevent deflection and provide quality cutting. The knife lowering timer allows increase the number of cuts per minute when working with small sheets. The controller controls the amount of knife lowering when cut not for the entire length of the blades, but also positions rear stop depending on the set parameters in cutting sheet. In the controller memory is stored information about cut materials and cutting sheets.

The upper cutting beam moves at an angle and along an arc in relation to the bottom, which provides an accurate cut on any metal thickness. Sturdy constructions, the frames and beams prevent deflection and provide quality cutting. The knife lowering timer allows increase the number of cuts per minute when working with small sheets. The controller controls the amount of knife lowering when cut not for the entire length of the blades, but also positions rear stop depending on the set parameters in cutting sheet. In the controller memory is stored information about cut materials and cutting sheets.

European Belgian shearing machine technology

High temperature annealing Frame, life-long maintenance free Specified NC and CNC operation system, Stable performance and simple operation

Imported Hydraulic system, reduce the breakdown

High quality alloy blade for cutting steel plate and stainless plate.

CNC operation system, Stable performance and simple operation High temperature annealing Frame, life -long maintenance free Heavy structure design, Strong and durable

High quality alloy blade for cutting steel plate and stainless plate.

| Model |

Cutting Thickness (mm) |

Cutting Length (mm) |

Back gauge Range (mm) |

Cutting Stroke (Pcs/min) |

Frame Throat (mm) |

Oil Volume (L) |

Motor Power (kw) |

| 4X2000 | 4 | 2000 | 750 | 18 | 100 | 140 | 5.5 |

| 6X2500 | 6 | 2500 | 750 | 17 | 100 | 200 | 7.5 |

| 6X3100 | 6 | 3100 | 750 | 15 | 100 | 230 | 7.5 |

| 6X4000 | 6 | 4000 | 750 | 8 | 100 | 250 | 7.5 |

| 8X2500 | 8 | 2500 | 750 | 17 | 100 | 290 | 11 |

| 8X3100 | 8 | 3100 | 750 | 15 | 100 | 350 | 11 |

| 8X4000 | 8 | 4000 | 750 | 8 | 100 | 400 | 15 |

| 13X2500 | 13 | 2500 | 1000 | 16 | 100 | 380 | 15 |

| 13X3100 | 13 | 3100 | 1000 | 13 | 100 | 450 | 15 |

| 13X4000 | 13 | 4000 | 1000 | 9 | 100 | 600 | 15 |

| 16X2500 | 16 | 2500 | 1000 | 9 | 100 | 500 | 22 |

| 16X3100 | 16 | 3100 | 1000 | 8 | 100 | 590 | 22 |

| 16X4000 | 16 | 4000 | 1000 | 7 | 100 | 590 | 30 |

| 20X2500 | 20 | 2500 | 1000 | 7 | 100 | 500 | 30 |

| 20X3100 | 20 | 3100 | 1000 | 7 | 100 | 590 | 30 |

| 20X4000 | 20 | 4000 | 1000 | 6 | 100 | 620 | 30 |

| 25X2500 | 25 | 2500 | 1000 | 6 | 100 | 820 | 45 |

| 25X3100 | 25 | 3100 | 1000 | 9 | 100 | 1000 | 45 |

| 30X3100 | 30 | 3100 | 1000 | 9 | 100 | 1300 | 55 |

| 30X4000 | 30 | 4000 | 1000 | 5 | 100 | 1400 | 55 |