123E-hydraulic Servo-controlled High Precision Press Brake

The hotel have about 689 rooms. They replace the mattress every three years. Couples and families are really like this hotel and give 8.9 high review score.In 2019, the customer just repeat the order for 2265pcs mattress. People like the comfortable of the hotel.

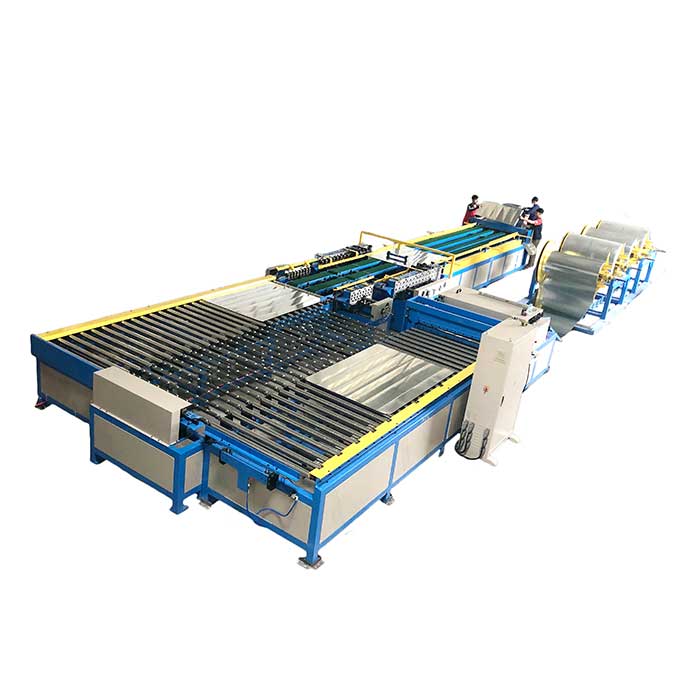

At the beginning of 2019, a Russian customer contacted us to help their steel processing plant increase the processing capacity of coil slitting. After technical communication, it was learned that the customer mainly increased the slitting capacity of cold-rolled steel coils with a thickness of 1-4mm this time, the maximum width of the processed coils was 1600mm, and the slitting speed of the machine reached 120m/min. maintenance and repair issues.

According to the customer’s technical requirements, we make adjustments to the configuration of the machine, and start production after the final confirmation from the customer and the receipt of the deposit. During production, we provide customers with equipment production progress and provide corresponding photos.

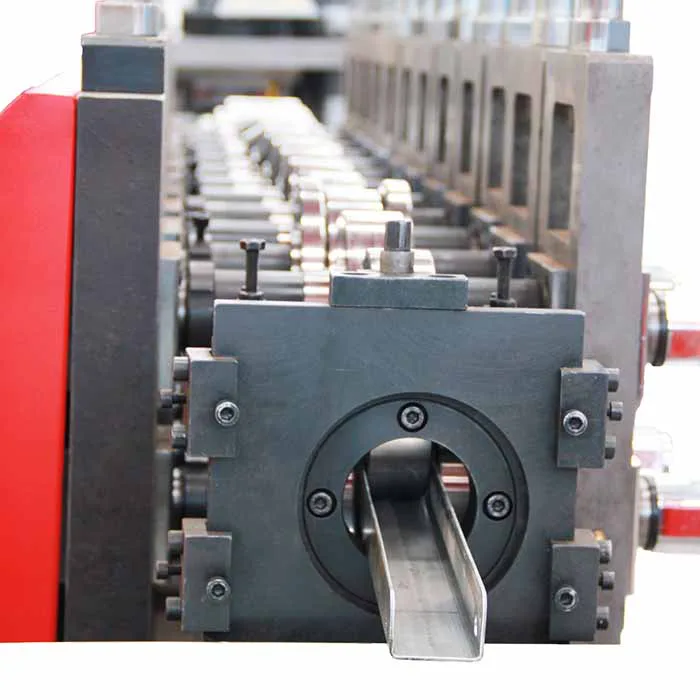

After the 90-day production period the machine is completed, we notify the customer to inspect the machine and prepare for shipment. Because the equipment needs to be fixed on the foundation to work on the whole line, but we do not have the corresponding foundation in the factory, we will test each item of the production line, including the uncoiler, the six-fold leveling machine, the slitting machine, the tensioner, the take-up The important parts such as the rolling machine are tested for operation.

In addition, the visiting customer technicians test the accuracy of the machine’s circular knives and shims, and all the accuracy test results meet the customer’s requirements.

The machine is now working at the customer’s factory and fully meets the customer’s requirements for its output.

Application