Ultimate Guides To Classfications of CNC Tools

- By:Metmac

- 2024-01-24

- 176

Table of Contents

CNC tools are important tools on CNC machine tools, they are used for cutting, more cutting drilling, tapping and other machining operations. There are many different types of CNC tools, each with its own specific purpose and suitable materials for machining. In this article, we will introduce the common CNC tool classifications.

1. Drill

A drill bit is a tool used primarily for drilling operations. According to its structure and use drill bits can be divided into the following types:

- Ordinary Drill Bits: For general drilling operations, commonly used in metal processing;

- Deep Hole Drill Bits: Used for deep hole drilling operations, enabling efficient machining of large deep holes;

- Laying Drill Bits: For drilling operations for laying electrical, piping and other pipelines;

- Skeleton drills: commonly used in the processing of non-metallic materials such as wood and plastic.

DRILL

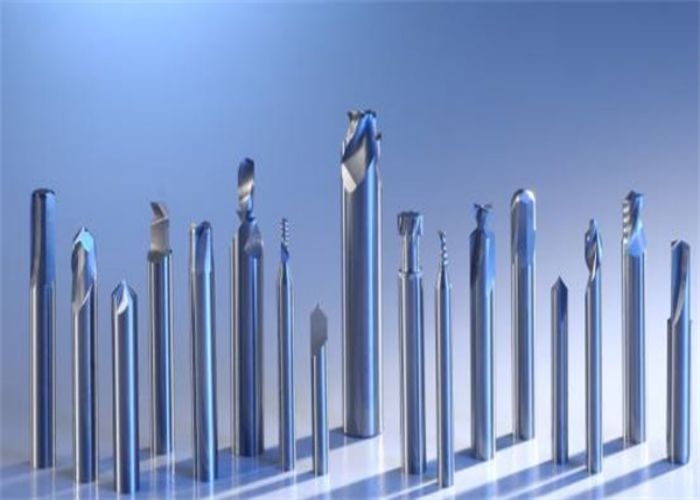

2. Milling Cutter

A milling cutter is a tool used to cut and dress the working surface. According to its cutting method and structure, milling cutter can be divided into the following types:

- Plane milling cutter: Used to cut the plane and straight line on the working surface;

- End milling cutters: For cutting right-angled and bevelled edges on the working surface;

- Vertical milling cutters: For realising diameters on the working surface;

- Turning cutters: For cutting external and internal circles on the working surface.

Milling Cutter

3. Toolholding

Tool fixtures are used to fix and clamp tools for machining operations on CNC machine tools. According to its use and structure, tool fixture can be divided into the following types:

- Clamp fixture: Commonly used to fix and clamp the tool to ensure its stability and accuracy;

- Magnetic fixtures: Utilise magnetic force to attach the tool and are suitable for machining operations on metals and magnetic materials;

- Pneumatic fixtures: Using air pressure to control the clamping force, suitable for high-speed machining and automated production lines.

Toolholding

4. Turning Tool

A turning tool is a cutting tool used for turning operations. According to its structure and cutting mode turning tool can be divided into the following types:

- External turning tool: used for turning the outer surface of the workpiece to achieve the processing of the outer circle;

- Internal turning tools: used for turning the inner hole of the workpiece to achieve the processing of the inner circle;

- Hole tools: tools for machining the inner surface of the hole.

Turning tool

5. Blades

Inserts are an important part of the cutting tools and they are in direct contact with the workpiece for cutting operations. According to their shape and use, inserts can be divided into the following types:

- T-shaped inserts: suitable for drilling, turning and other operations, with high cutting efficiency;

- Triangular inserts: suitable for turning and milling operations with high cutting stability;

- Square inserts: suitable for cutting the plane and straight line of the workpiece, with high cutting precision.

Blades

The above is a common classification of CNC tools. In CNC machining, the reasonable selection and use of suitable tools is to ensure that the processing quality and efficiency of the important factors. According to the processing needs, choose the right CNC tool can effectively improve the processing efficiency and processing quality to reduce production costs and improve the competitiveness of enterprises. We hope to be able to help you If you need to know more about CNC cutting tools, Guangzhou METMAC Company Limited specialises in providing all kinds of machine tools and accessories, welcome to consult and exchange.

-

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04 -

The Environmental Benefits of Using Duct Board Grooving Machines

2024/09/03

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26