Types And Characteristics of Laser Processing Head

- By:Metmac

- 2024-07-19

- 115

Laser processing head is an important part of laser processing equipment, according to different application needs, laser processing head can be divided into a variety of types, each type has its unique characteristics and scope of application.

Here are some common types of laser processing heads and their characteristics:

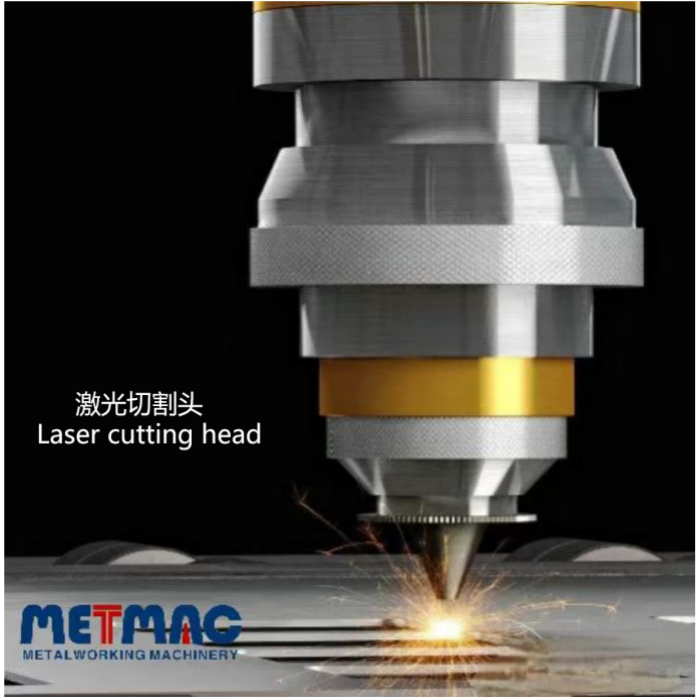

1. Laser Cutting Head

1). Melting cutting head: suitable for partial melting of the workpiece through the air jet melting material, suitable for iron materials and titanium non-oxidation cutting.

2) Evaporation cutting head: is suitable for high energy high density laser head beam to heat the workpiece to increase the temperature, so that the material evaporates into steam in a very short time, is suitable for extremely thin metal and non-metallic materials.

3) Control fracture cutting head: suitable for brittle materials, through the laser head beam heating for high-speed and controlled cutting, crack.

4) oxidation melting cutting head ( laser flame cutting head): usually use inert gas cutting.

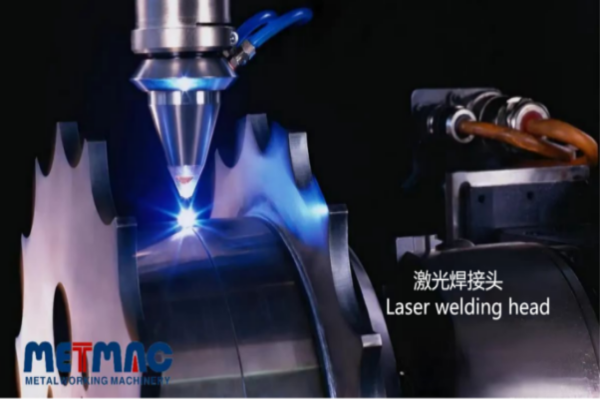

2. Laser Welding Head

1). Coaxial vision single-focus laser welding head: suitable for micro-pitch mounting devices and Chip parts welding,spot shape is round.

2) Coaxial vision square spot laser welding head:through advanced optical shaping method to make the focused spot square,effectively eliminate halo, halo and other focusing phenomena.

3). Coaxial visual strip spot laser welding head:spot shape is rectangular, has the characteristics of high uniformity.

4). Coaxial visual strip spot XY adjustable laser welding head:spot shape is similar to strip spot welding head, X,Y axis is adjustable square, spot strip length and width can be adjusted.

5). Coaxial vision laser focusing welding head:spot shape is round, can focus collimation,spot size is adjustable.

3. Laser Marking Head

Galvanoscopic scanning system:suitable for large format marking, through the computer to control the reflection Angle of the mirror, to deflect the laser beam, to leave a permanent mark on the surface of the material.

Each type of laser processing head is designed and characterized to meet specific processing needs, such as cutting, welding or marking. Choosing the right laser processing head is very important to improve processing efficiency, quality and precision.

METMAC specializes in providing laser cutting machine accessories, laser focus mirror, cutting head, cutting nozzle, laser protection sheet, etc. Welcome to consult and exchange.

-

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04 -

The Environmental Benefits of Using Duct Board Grooving Machines

2024/09/03

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26