The Principles of Material Selection For CNC Tools

- By:Metmac

- 2024-02-03

- 174

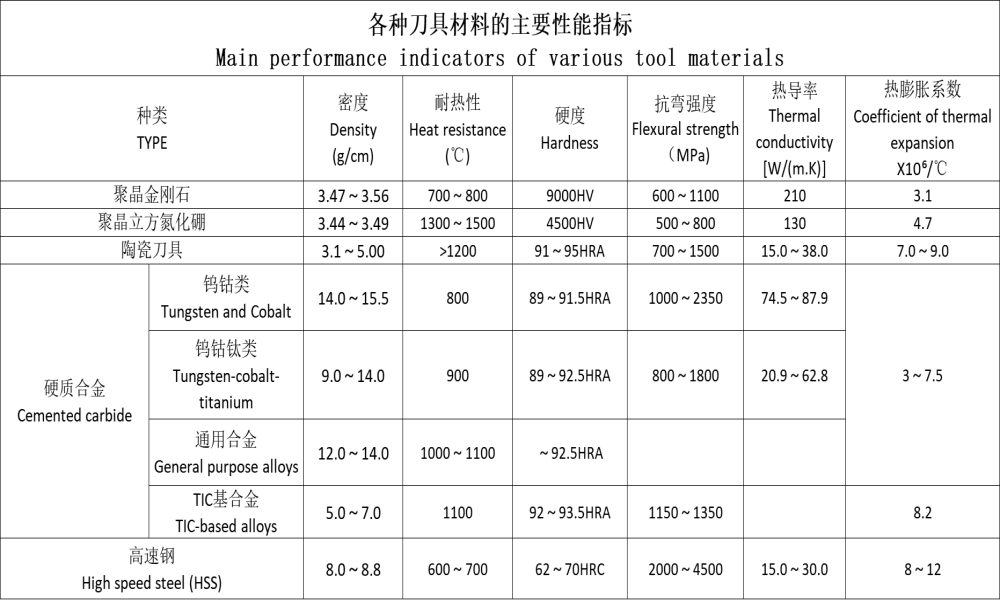

Currently widely used CNC tool materials are mainly diamond tools, cubic boron nitride tools, ceramic tools, coated tools, carbide tools and high-speed steel tools. The total number of cutting tool material brand, its performance varies greatly. The table below shows the main performance indicators of various cutting tool materials.

Cutting tool materials for CNC machining must be selected according to the nature of the workpiece and processing. The selection of cutting tool materials should be reasonably matched with the processing object, cutting tool materials and processing object matching, mainly refers to the mechanical properties of the two, physical properties and chemical properties to match, in order to obtain the longest tool life and maximum cutting productivity.

1. cutting tool materials and machining object mechanical properties matching cutting tool and machining object mechanical properties matching problem mainly refers to the tool and workpiece material strength, toughness and hardness and other mechanical properties parameters to match. With different mechanical properties of the tool material suitable for processing the workpiece material is different.

① Tool material hardness order: diamond tools > cubic boron nitride tools > ceramic tools > carbide > high-speed steel.

② The bending strength of the tool material in the order of: high-speed steel > carbide > ceramic tools > diamond and cubic boron nitride tools.

③ cutter material toughness size order: high-speed steel > carbide > cubic boron nitride, diamond and ceramic tools, high hardness of the workpiece material, must be processed with a higher hardness of the tool, the hardness of the tool material must be higher than the hardness of the workpiece material, the general requirements of the 60HRC or more. The higher the hardness of the tool material, the better its wear resistance. For example, when the amount of cobalt in the cemented carbide increases, its strength and toughness increases, the hardness decreases, suitable for roughing; when the amount of cobalt decreases, its hardness and wear resistance increases, suitable for finishing.

With excellent high-temperature mechanical properties of the tool is particularly suitable for high-speed cutting. Ceramic tools with excellent high temperature performance so that it can cut at high speeds, allowing the cutting speed can be increased by 2 to 10 times than cemented carbide. Matching of cutting tool materials and physical properties of machining objects. Cutting tools with different physical properties, such as high thermal conductivity and low melting point of high-speed steel cutting tools, high melting point and low thermal expansion of ceramic cutting tools, high thermal conductivity and low thermal expansion of diamond cutting tools, etc., suitable for processing of different workpiece materials.

When processing poor thermal conductivity of the workpiece, should be used in better thermal conductivity of the tool material, so that the cutting heat can be quickly transferred out and reduce the cutting temperature. Diamond due to thermal conductivity and high thermal diffusivity, cutting heat is easy to dissipate, will not produce a lot of thermal deformation, which requires high dimensional accuracy of precision machining tools is particularly important, The heat resistance of various cutting tool materials

① Heat-resistant temperature of various cutting tool materials: 700~8000C for diamond tools, 13000~15000C for PCBN tools, 1100~12000C for ceramic tools, 900~11000C for TIC(N)-based cemented carbide, 800~9000C for WC-based ultra-fine grain cemented carbide, 600~7000C for HSS.

② The order of thermal conductivity of various tool materials:PCD>PCBN>WC-based cemented carbide>TiC(N)-based cemented carbide>HSS>Si3N4-based ceramics>A1203-based ceramics.

③ The thermal expansion coefficient of various cutting tool materials in the order of magnitude: HSS>WC-based cemented carbide>TIC(N)>A1203-based ceramics>PCBN>Si3N4-based ceramics>PCD.

Thermal shock resistance of various cutting materials in the following order: HSS>WC-based cemented carbide>Si3N4-based ceramics>PCBN>PCD>TiC(N)-based cemented carbide>A1203-based ceramics.

3. Cutting tool materials and the chemical properties of the processing object match.

4. Cutting tool materials and processing object chemical performance matching problem mainly refers to cutting tool materials and workpiece materials, chemical affinity, chemical reaction, diffusion and dissolution and other chemical performance parameters to match. Material different tools suitable for processing the workpiece material is different.

① various cutting tool materials bonding temperature (and steel) for: PCBN> ceramic> carbide> HSS,

② various cutting tool materials oxidation resistance temperature is high and low (and steel) for: PCBN> ceramic> carbide> HSS.

② various cutting tool materials, high and low oxidation temperature: ceramics > PCBN > carbide > diamond > HSS

③ the size of the diffusion strength of various cutting tool materials (for steel): diamond > Si3N4-based ceramics > PCBN > A1203-based ceramics. The diffusion strength size (for titanium) is: A1203-based ceramic>PCBN>SiC>Si3N4>diamond.

Generally speaking, PCBN, ceramic tools, coated carbide and TCN-based carbide tools are suitable for CNC machining of ferrous metals such as iron and steel; while PCD tools are suitable for machining non-ferrous materials such as A1, Mg, Cu, and their alloys and non-metallic materials. Table 3-3-2 lists some of the above tool materials suitable for machining workpiece materials.

The following table lists some of the workpiece materials that various tool materials are suitable for machining.

-

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04 -

The Environmental Benefits of Using Duct Board Grooving Machines

2024/09/03

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26