How to Select the Best Round Duct Making Machine for Your Specific Needs

- By:Metmac

- 2024-09-06

- 176

Selecting the best round duct making machine for your unique requirements is crucial for optimizing productivity and meeting industry standards. This comprehensive guide will provide you with a step-by-step approach to help you make an informed decision.

Considerations for Selecting a Round Duct Making Machine

1. Duct Size Capacity

Determine the maximum and minimum duct sizes you need the machine to produce. This will help you narrow down your choices and ensure that the machine you select can meet your present and future production needs.

2. Production Volume

Estimate the volume of ducts you need to produce per hour or per week. Higher production requirements will necessitate a machine with a larger capacity and faster production speeds.

3. Material Compatibility

Consider the types of materials you need to work with, such as galvanized steel, stainless steel, or aluminum. Ensure that the machine supports the desired materials to avoid compatibility issues.

4. Features and Capabilities

Assess the features and capabilities that are essential for your operations. This may include automated seam welding, flanging, notching, and beading functions. Determine which features are necessary to streamline your production process.

5. Space Requirements

Measure the available space in your workshop and determine the dimensions of the machine that will fit comfortably without obstructing other operations. Consider the size of the ducts you need to produce and the need for additional equipment, such as a coil car or duct stretcher.

6. Energy Efficiency

Energy consumption is an important factor to consider. Look for machines that incorporate energy-efficient designs or use low-power components to reduce operating costs.

7. User Interface and Maintenance

Select a machine with an intuitive user interface that simplifies operations and minimizes user errors. Additionally, consider the availability of routine maintenance, spare parts, and technical support to ensure smooth operation and longevity.

8. Budget and ROI

Establish a realistic budget for your machine purchase. Consider the return on investment (ROI) in terms of increased productivity, reduced labor costs, and improved product quality. Calculate the expected cost savings and project the payback period to justify your investment.

Additional Tips

Request machine demonstrations to see the equipment in action and evaluate its capabilities firsthand.

Consult with industry professionals for recommendations and advice based on their experiences.

Read online reviews and compare different machines from reputable manufacturers to gather unbiased opinions.

Look for equipment that complies with relevant industry standards and safety regulations.

-

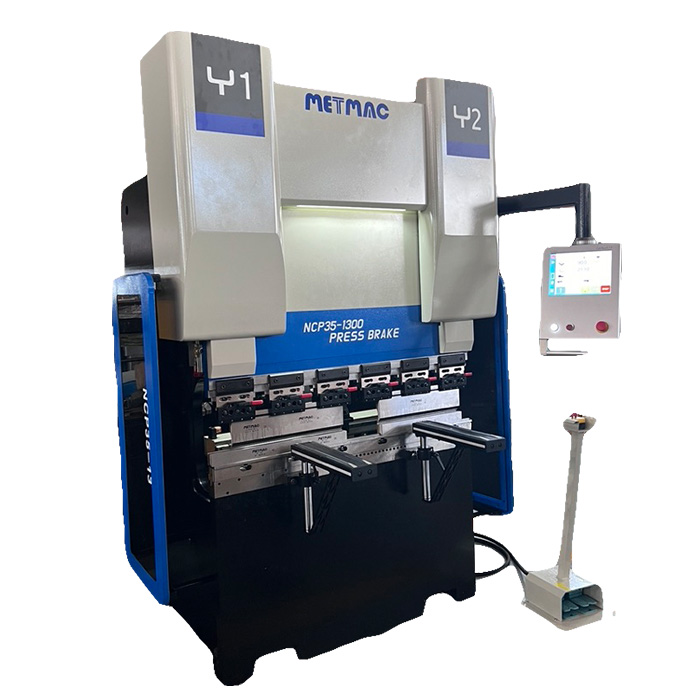

Bending Brakes: The Art of Precision in Metal Forming

2025/11/11 -

Sheet Metal Cutting Machine: The Foundation of Precision Fabrication

2025/11/11 -

Sheet Bending Machine: The Cornerstone of Precision Metal Fabrication

2025/11/11 -

Sheet Metal Bending Machine: The Precision Force Behind Modern Fabrication

2025/11/11

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26