How To Choose Core Accessories For Fiber Laser Cutting Machines ?

- By:Metmac

- 2023-05-06

- 382

How to choose the core accessories for fibre laser cutting machine? It is well known that fibre laser cutting machines are the ideal processing tool for the metal processing industry due to their high precision and efficiency. However, all these technical advantages are concentrated in the laser equipment accessories. The same fibre laser cutting machine uses different laser accessories, and the final cutting effect will be different. Therefore, if users want to buy a suitable for their own industry, cost-effective fiber laser cutting machine, its accessories with the extremely important, Metmac teaches you to understand the fiber laser cutting machine core accessories of quality selection.

1-Fibre Laser

The fibre laser is the head attachment of the fibre laser cutting machine and is the core “power source” of the fibre laser cutting machine. Compared to other lasers, these two fibre lasers have the advantages of higher cutting efficiency, more reliable quality assurance, longer service life and lower maintenance costs.

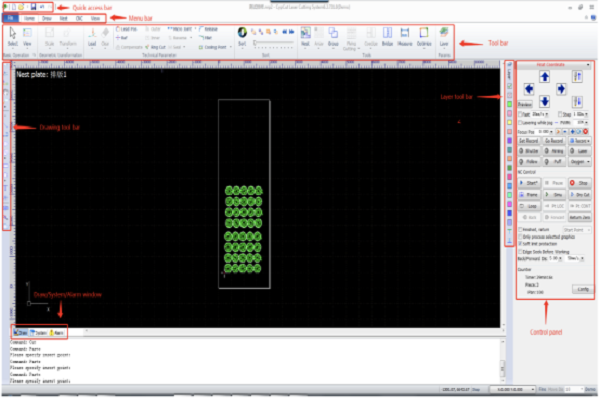

2-Cutting control system

The control system is the dominant operating system of the fibre laser cutting machine. Its quality determines the stable operational performance of the fibre laser cutting machine. The system mainly controls the machine tool, realises the X, Y and Z axis movements and also controls the output power of the laser.

3-Cutting head

The laser cutting head is a laser output device consisting of a nozzle, a focusing lens and a focus tracking system. The cutting head of a laser cutting machine will follow a set cutting path, but the height of the laser cutting head needs to be adjusted and controlled according to different materials, different thicknesses and different cutting methods.

4-Servo motors

A servo motor is an engine that controls the operation of mechanical components in a servo system and is a device that assists the motor with indirect variable speed. Servo motors allow very precise control of speed and positional accuracy and can convert voltage signals into torque and speed to drive the controlled object. High-quality servo motors ensure the cutting accuracy, positioning speed and repeatability of laser cutting machines.

5-Fibre optics

This is the heart of the laser cutting machine. As imported laser tubes are very expensive, generally in the tens of thousands of RMB, most laser cutting machines use domestic optical fibres. The quality of domestic optical fibres varies and there is a wide price gap. The service life of better quality fibres is generally around 8000 hours.

6-Laser lenses

Related to the power of the fiber laser cutting machine, divided into imported lenses and domestic lenses. Imported lenses and domestic lenses use effect and service life also differs greatly.

The above is the core accessories of fiber laser cutting machine, if you do not know how to match, we will help you match well according to your needs, we have a full set of laser cutting machine accessories, brand and specifications are complete, welcome to consult and exchange.

-

Metal Sheet Forming Machine: The Engine of Modern Fabrication and the METMAC Standard

2025/12/30 -

Laser Cutting Machine for Steel Plate: Precision Redefined for Modern Fabrication

2025/12/30 -

Metal Curving Machine: Shaping Strength with Precision and the Art of METMAC Engineering

2025/12/30 -

Shear Metal Cutting Machine: Precision, Power, and the METMAC Standard

2025/12/30

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Latest Technological Advancements in Rectangular Duct Machines

2024/05/11 -

Integrating Automation with Rectangular Duct Machines for Enhanced Productivity

2024/05/11 -

Metal Shear Machines- Essential Tools for Precision Metal Cutting

2024/05/11 -

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26