How Do You Do the Seam Lock Connection for the Hvac Duct Fabrication

- By:Metmac

- 2022-07-09

- 241

In ventilation and air-conditioning duct projects, the ducts and fittings made of thin metal plates can be used with lock seam, riveting, welding, and lock seam are the most common connection which includes Pittsburgh lock seam, drive cleat seam, standing seam, double seam lock, snap lock seam, hemmed S clip, Connection form of sheet metal mainly depends on the plate thickness and material, galvanized steel and various types of the steel plate of the composite protective layer should be connected by seam lock or riveting. The connection of the anti-corrosion performance of the layer and the composite protective layer.

If the thickness of the thin steel air duct is generally less than or equal to 1.2mm, the seam lock joint should be used. Connection: For plate thickness greater than 1.2mm, welding can be used. Air duct made of galvanized steel sheet if the plate thickness is less than or equal to 1.2mm, use bite connection; if the plate thickness is greater than 1.2mm, use rivets to avoid damage to the galvanized layer by welding.

The seam lock connection is to use the hemming method to hook the edges of the plates to be connected to each other. Roll forming by METMAC Pittsburgh lock former, then hook each other, seam lock and press tightly. The seam lock be used as much as possible, the seam lock can increase the stiffness of the duct. Seam lock connection is generally suitable for thicknesses less than 1.2mm ordinary thin steel plate and galvanized thin steel plate, aluminum plate with thickness less than 1.5mm, stainless steel plate with thickness less than 0.8mm.

1. The Profile of Seam Lock and Its Scope of Application

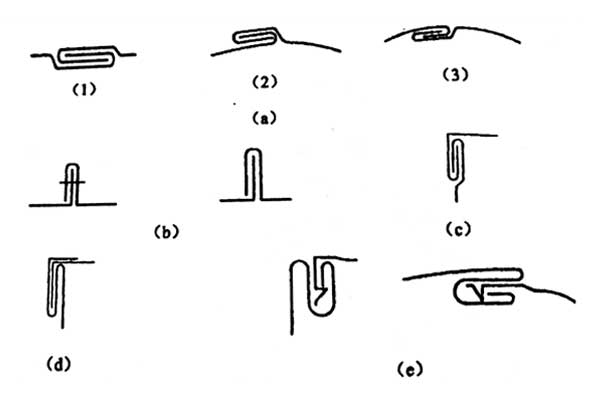

Most popular forming seam lock includes lock seam are the most common connection which includes Pittsburgh lock seam, drive cleat seam, standing seam, double seam lock, snap lock seam, hemmed S clip, etc., as shown in Figure 4-1.

The Pittsburgh lock seam is suitable for the splicing and round joints of low, medium and high pressure duct system plates longitudinal closed seams of air ducts or fittings.

The drive cleat is mostly used for the horizontal connection or longitudinal joint of the circular duct, and is used for the circular elbow no rivets can be added to the seams.

Corner lock seam and joint angle bite are suitable for low, medium and high pressure rectangular duct systems the four corners of the duct and fittings are closed. The corner lock seam is also more commonly used for non-folding machines and lock manually by lock former machine.

The snap lock is convenient for transportation and assembly, but it is strict the tightness is poor, and it is suitable for the four corners of the duct and fittings in the low and medium pressure rectangular duct system. The seam lock of the low-pressure circular duct and the low-pressure circular duct should be adopted if it is applied to the occasions with high tightness requirements by sealing.

-

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14 -

How to Optimize Your Laser Sheet Cutting Machine for Maximum Performance

2024/09/12 -

How to Maximize Efficiency with Modern Sheet Metal Working Machines

2024/09/04 -

The Environmental Benefits of Using Duct Board Grooving Machines

2024/09/03

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26