Common Problems Encountered In Sheet Metal Bending

- By:Metmac

- 2023-03-21

- 339

-

Bending Principle

The essence of bending is the cold deformation process of bending the sheet into a certain shape, a pressure processing method at room temperature, which can bend metal materials, non-metal materials and composite materials. In this processing method, the workpiece relies on the bending die and hydraulic equipment to complete the process, the dimensional accuracy of the bent parts by the upper and lower die and bending equipment to ensure that the forming process is: in a certain size of the plate material.

Bending force is exerted by the upper die, the support point in the lower die to produce a reaction force to form a bending moment, forcing the plate deformation, the final bending angle of the plate by the upper die into the depth of the lower die mouth decision.

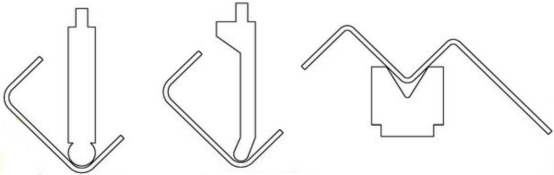

The main working part of the CNC bending machine consists of backstop,. The upper die and lower die composition. Backstop is to control the bending line position of the working parts, the upper die and lower die is used to control the workpiece bending angle and internal radius, the workpiece is mainly determined by these three parts. Here, As follows, it needs clicking the pictures for more details.

( Click Picture For More Details)

-

Problems In Bending Processing And Solutions

In the production of sheet metal parts for electric locomotives, many grooves and multi-channel bending workpieces cannot be produced directly according to the design drawings, or they cannot be produced with the existing molds, some of which are used. Therefore, we need to consider and calculate in advance before bending to ensure the bending size by reverse pre-bending, choosing the right tooling or selecting the right lower die opening.

-

Normal Bending Mode

-

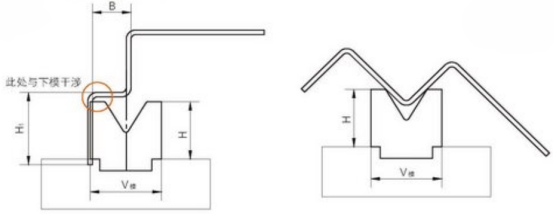

The normal bending mode is shown in Figure 1.

-

Sheet metal bending interference prediction

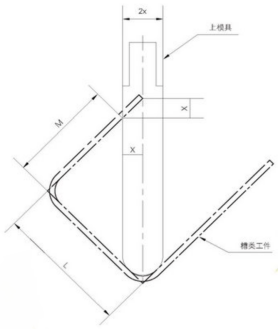

When encountering this kind of sheet metal parts with high leg groove, how to quickly determine whether the bending can be completed or not requires several calculations, and the corresponding dimensions are shown in Figure 3.

When L-M<1.5x, the workpiece can be bent without interference. When L-M>1.5x, the workpiece cannot be bent and interference occurs.

-

Interference Solution

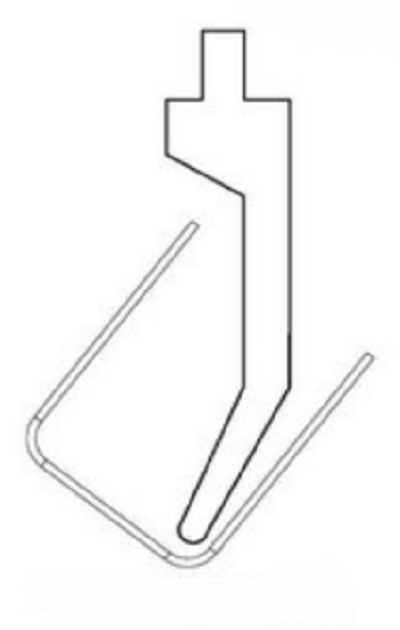

(1) If the slotted workpiece produces bending interference, you can choose the gooseneck upper die for bending, which can avoid the interference between the bending edge of the workpiece and the bending machine or the upper die and ensure the bending size of the workpiece, as shown in Figure 4.

( Click Picture For More Details)

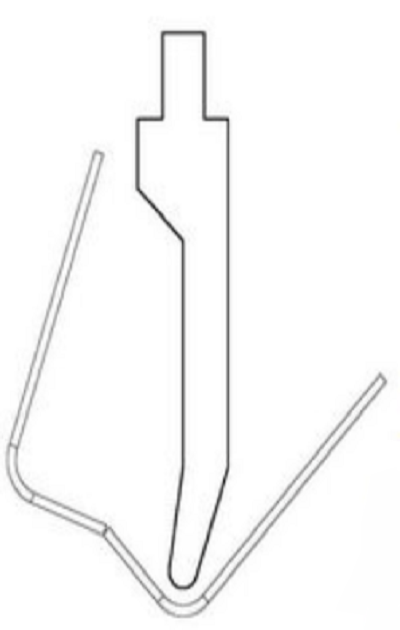

(2) If the slotted workpiece produces bending interference and there is no suitable gooseneck upper die available, pre-bending can be done in the middle of the bending without affecting the use requirements, as shown in Figure 5, by artificially increasing the bending angle to ensure that the workpiece can be bent normally, and finally flattening the pre-bending point with a flat tire mold to ensure the product quality requirements.

(3) multi-bending workpiece bending, if H or B < V die/2 bending, the workpiece and the lower die opening and table interference, then the choice of the lower die and bending order is very important, you can choose the following methods: ① choose H>H high size lower die to ensure normal bending workpiece; ② choose B> V die/2 lower die opening to ensure normal bending workpiece; ③ no high size lower die can change the bending order, first pre-deformation middle bending to a certain angle, then bending at the short side, then the third bending forming, and finally re-pressing the middle bending to the size and angle required by the process, so as to ensure the workpiece process size, as shown in Figure 6.

( Click Picture For More Details)

(1) Cause analysis. Sheet metal parts bending, often in the bending tensile surface cracks, resulting in the mechanical properties of the workpiece damage, can not meet the process requirements, resulting in the scrapping of the workpiece, resulting in – certain economic losses, the main reasons are the following.

① plate has a special crystal structure and rolling grain direction, bending parallel grain direction prone to fracture;

② the choice of bending radius R angle is too small.

③ the R angle of the lower die V-groove is small.

④ poor material properties.

-

Prevention And Control Measures.

① when the material, the plate will be rotated to the bending vertical direction for cutting (even if the material bending direction is perpendicular to the grain)

② increase the upper die R angle.

③ use large R angle of the lower die processing.

④ Use materials with good performance.

-

Sheet Metal Unfolding Calculation

There are two common methods of unfolding: neutral layer unfolding and 3D software unfolding. Neutral Layer Unfolding Method

Definition of neutral layer: When a sheet is extruded by external forces, the outer layer is stretched and the inner layer is extruded, a transition layer is bound to exist inside the section. Neutral layer in the bending process, its length and bending before the length of the same, basically remain unchanged, as shown in Figure 7.

-

Mastering Form and Force: A Guide to Modern Metal Plate Bending Machines

2025/12/16 -

Demystifying Sheet Metal Laser Cutting Machine Price: The METMAC Value Perspective

2025/12/16 -

Metal Sheet Machinery: The Engine of Modern Fabrication and the METMAC Advantage

2025/12/16 -

Beyond the Bend: The Power and Precision of the Modern Sheet Profile Machine

2025/12/16

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26