Air Conditioning and Ventilation Design of Radiotherapy Room in Hospital

- By:Metmac

- 2022-07-12

- 336

Abstract

The rapid developments of hospital radiotherapy equipments have made a higher requirement to the HVAC design than ever before. Associating with an example of the ventilation and air conditioning design of a radiotherapy room, detailed announcements and methods were presented, including decisions of reasonable ventilation schemes, air conditioning loads, exhaust ventilation and radiation protection measures.

Keywords

radiotherapy equipment, ventilation system, air conditioning system.

Preface

With the advancement of science and technology, the development of medical equipment has sprung up and is full of vitality. At present, my country is in a critical period of medical and health care reform. It is not difficult to foresee that more high-tech medical equipment will be introduced and used in the near future. This requires HVAC dust machine designers to keep abreast of the development of modern medical technology in order to study, design a reasonable and correct HVAC system, ensure the normal use of medical equipment, and ensure the safety of personnel and the environment.

Radiotherapy plays an important role in hospitals. The most common radiotherapy equipment is electron accelerators. There are two types of electron accelerators. One is a linear accelerator; the other is an induction accelerator. The heat dissipation of the linear accelerator is about 7kW. Mainly in the rack area, the air conditioning should be designed to reach this area first; the heat dissipation of the induction accelerator is about 41 kW. The heat output of the modulation cabinet and power distribution room is about 3kW, and the heat output of the accelerator control room is 1.0 kW.

1. Air Conditioning and Ventilation System Design

1.1 Air conditioning system design

First of all, it is necessary to correctly calculate the cold / heat load of the linear accelerator machine room, which includes: heat input through the enclosure structure, solar radiation heat entering through external windows and skylights, human body heat dissipation, lighting and equipment and other internal heat sources. , The heat brought by fresh air and make-up air. This requires the designer to accurately understand the heat dissipation of the related equipment and the requirements for ventilation in the linear accelerator room. Generally, the fresh air exchange rate is large, and the load of fresh air and supplementary air accounts for a large proportion of the total load, so as to determine safety , Reasonable ventilation rate is particularly important. Compared with general public building air conditioning load, another load characteristic is the heat generation of the equipment. Because the heat generation of the equipment is large, when calculating the load, you must investigate the heat generation of the actual equipment. In the absence of specific data, you can refer to the parameters provided above.

Due to the importance of equipment, air conditioning in these places can be in the form of full air system or direct refrigerant evaporative cooling. Refrigerant pipes and condensate pipes or air pipes entering and exiting the machine room can be arranged in a circuitous manner in the form of a “labyrinth”. At the same time, a certain length of lead plate should be used for outsourcing protection when the pipeline passes through the machine room to prevent radiation leakage through the pipeline when the radiotherapy equipment is working. An independent condensate piping system should be used in the exfoliation room to prevent pollutants and rays from flowing through the condensate pipe to other rooms during the operation of the linear accelerator. The discharge of condensate in the radio therapy room should be inspected and approved by the corresponding department.

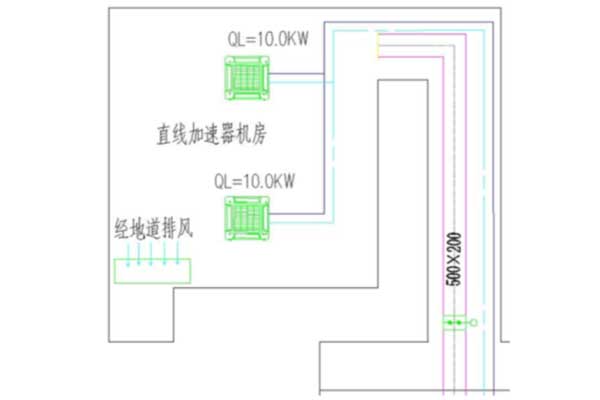

Figure 1 shows the layout of refrigerant pipes and fresh air pipes in a linear accelerator room. The air conditioning system of the linear accelerator room is in the form of VRV+ independent fresh air system, and the fresh air is processed by a direct evaporative cooling fresh air unit. Because the fresh air (supply air) of the radiotherapy room is processed by the direct evaporative cooling equipment of the refrigerant, it is difficult for the existing equipment to process the fresh air to the required state. In addition, the external wall (near the earth wall) of the house has serious water seepage, which increases the indoor humidity load Therefore, the indoor unit needs to bear part of the fresh air load and additional wet load. Therefore, the indoor unit selected in the linear accelerator room has a rated total cooling capacity of 20 kW (if the indoor wet load is too large, you can consider installing a mobile dehumidifier). Two indoor units with a rated cooling capacity of 10kW and four-side air outlets, and 2.5 kW side air supply indoor units are used in the control room.

Figure 1 Air conditioning diagram of the linear accelerator room.

1.2 Ventilation system design

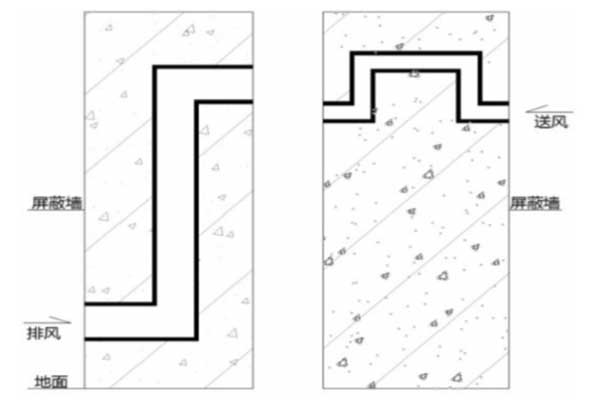

When the radiotherapy machine is working, the air will be ionized, which will produce harmful nitrogen oxides and ozone. The density of ozone and nitrogen oxides are both greater than the density of air. At the same time, considering that the gas fire extinguishing gas usually uses heptafluoropropane, its The density is higher than that of air. Based on the above considerations, the air flow organization form of upper and lower rows is adopted. The air exhaust in the room should be set in the lower part of the room and far away from the door and the area where people often move. In order to prevent the leakage of pollutants at the moment the door is opened after the radiotherapy machine is finished, the design idea of maintaining the negative pressure in the room can be adopted, and the fresh air volume and the exhaust air volume can be configured at a ratio of 0.8. In order to prevent the leakage of pollutants in the exhaust duct, the duct can be installed in the underground civil air duct.

The hospital’s valuable equipment such as accelerators, MRI and ECT rooms are equipped with gas fire extinguishing systems. The HVAC professional design requires the installation of an emergency exhaust system after a fire. In order to simplify the pipeline, a set of dual-use systems is adopted in this design. The design method, that is, the usual exhaust and the exhaust after the accident share a system, and it can also reduce the number of pipelines crossing the protective wall. The environmental assessment report requires that the number of air changes in the radiotherapy room is greater than 4 times / h. For safety reasons, the exhaust air exchange rate of the radiotherapy room can be designed as 6 times per hour, so the exhaust fan is determined by using 4 computer rooms at the same time. Air volume. Although nitrogen oxides and ozone pollute the air, they produce a small amount and have little impact on the environment, and can be directly discharged into the atmosphere. In addition, in order to prevent the fresh air from being mixed with pollutants in the exhaust air, the outdoor air outlet should be far away from the new air outlet, and the new air outlet should be arranged upstream of the incoming flow or the air outlet should be discharged above the roof with a duct.

The main heat dissipation part (rack area) of the radiotherapy equipment is arranged in the area close to the exhaust outlet to facilitate the timely discharge of the heat dissipation of the equipment or the cold air to the heating part as much as possible, so as to quickly cool the linear accelerator, protect and extend the equipment The role of service life. The exhaust duct should be insulated in the equipment room to prevent condensation in the exhaust duct at the equipment room.

2. Anti-Ray Measures

In order to prevent the pollution of the non-radiation area by the rays generated by the linear accelerator during operation, the air conditioning and ventilation system must not only meet the requirements of indoor air temperature, humidity and cleanliness, but also take effective measures to prevent rays from leaking through the tube wall and pipeline.

Because the radiation has a conductive effect in metal, metal pipes should be avoided for the pipes entering and leaving the radiotherapy room. Non-metallic pipes (such as glass fiber reinforced plastics, glass magnesium composite air pipes, etc.) are used for air conditioning, return air ducts and exhaust ducts to prevent radiation.

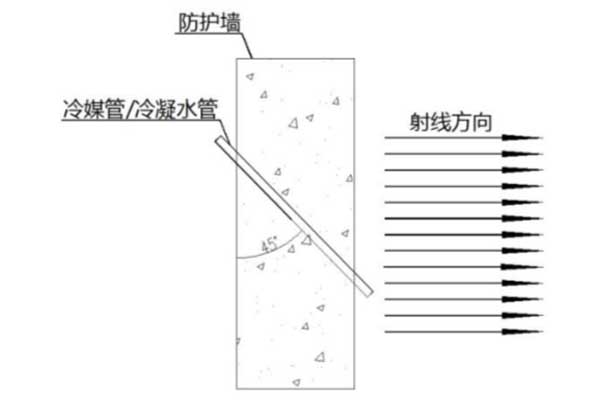

The radiation will pass through the tuyere, etc. into the duct. If no measures are taken, the radiation will easily be transmitted through the duct to the outside of the linear accelerator room, causing radiation hazards to outsiders. The principle of low ray reflectivity can be used, and multiple right-angle bends can be designed when designing air ducts and other pipelines, so that there is not much ray left after multiple reflections, as shown in Figure 2. When the refrigerant tube / condensate tube enters and exits the linac machine room, make the tube and the ray direction at 45°, as shown in Figure 3.

Figure 2 Schematic diagram of the duct passing through the shielding wall.

Figure 3 Schematic diagram of cold coal pipe / condensate pipe passing through the protective wall.

The embedded pipe will reduce the local thickness of the protective wall, as shown in Figure 2 and Figure 3. Therefore, according to the dose limit of occupational radiation workers (the weekly dose limit is 0.02 mSv / w), it is necessary to check whether the minimum local thickness meets the requirements. Use formula (1) to calculate: y=r2.H_w(W・U・T.n).

(1) Where: y is the attenuation factor; Hw is the weekly dose limit, which is taken as 0.02 mSv / w; r is the distance between the target (beam exit) and the protection point; W is the weekly work load, which is taken as 720 mSv / w; U Is the beam orientation factor, which can be 1,1/4, 1/8.*.; T is the residence factor, which can be 1,1/4, 1/8.*; n is the safety factor, which is 2.

According to different values of U and T, the wall attenuation factors of different orientations can be calculated, and the thickness of the required shielding wall can be obtained by checking the “y-ray shielding parameter manual”. In the case of insufficient thickness, it should be The lead plate is used for outsourcing the pipe. The thickness of the lead plate is related to the thickness of the weakened wall of the enclosed pipe. A lead plate with a thickness of approximately 1 mm is equivalent to the radiation attenuation network of a 100 mm thick concrete wall.

The shielding wall of the linear accelerator engine room should be cast at one time, so the air supply pipe, condensate pipe, refrigerant pipe and other pipelines should be embedded during construction. As shown in Figures 2 and 3, the main methods of embedded pipes are oblique 450 embedded pipes, “Z” shaped embedded pipes and “U” shaped. In order to reduce the leakage of radiation, the embedded pipes should follow the premise of satisfying their functions. Under the principle of ensuring that the radiation hazard to the human body is within a safe range, the pre-embedded pipes should be arranged in areas with small radiation levels, and the area of the buried pipes should be minimized. During construction, all pre-embedded pipes must be carried out at the same time as the concrete pouring. Finished at once.

Induced radioactivity comes from induced radionuclides, such as H,’Be, “C, “N, SO, 4lAr, etc., when the air in the linear accelerator treatment room is irradiated with high-energy particles. When the ray energy is above 10 MV, induced radioactivity will be generated. The half-life of induced radionuclides varies in length, with the shortest half-life being only 7.3s and the longest reaching 121.53d. Therefore, when the accelerator is off, the induced radioactivity decays very quickly in a short period of time, and the change of induced radioactivity tends to be flat in a long time. The existence of long half-life inductive radionuclides causes a certain level of induced radioactivity in the computer room under shutdown conditions. Therefore, after the accelerator stops working, the protective door should not be opened in time. Instead, ventilation and exhaust should be continued for a period of time. The time should be controlled so that the engine room can be ventilated at least once to facilitate the discharge of ammonia oxide, ozone and induced radionuclides. Thereby creating a clean indoor environment. Since the ventilation frequency in this design is designed as 6 times / h, medical staff should enter the computer room after the accelerator stops working for no less than 10 minutes.

3. Comparison of Heat Recovery Forms

The so-called heat recovery refers to the recovery of waste heat (cold) or waste heat (cold) inside and outside the building. According to the survey, the energy consumption of fresh air processing in air-conditioning projects roughly accounts for 25% to 30% of the total energy consumption of the building. It is as high as 40%. It can be seen that the air conditioning consumes a lot of energy to process fresh air. The energy available in the exhaust air of an air-conditioned room is considerable, and if it is recycled, good benefits can be obtained in terms of energy saving and environment. To this end, my country’s “Design Standards for Energy Conservation of Public Buildings” (GB50189-2005) issued in April 2005 clearly stated that when the technical and economic analysis is reasonable, designers should give priority to the recovery of exhaust energy 4s].

At present, there are the following forms of heat recovery: First, through a total heat recovery device (such as a rotary heat exchanger, a total heat ventilator, etc.), the fresh air directly obtains the waste heat (cold) from the exhaust air. If the total heat recovery is adopted In summer, the fresh air can achieve the purpose of cooling and dehumidification, and in winter, the fresh air can be heated and humidified; second, through the sensible heat recovery device (such as heat pipe, etc.), the fresh air can achieve the purpose of cooling/heating; For air-cooled heat pumps, the condenser recovers the intercooling capacity of the exhaust air in summer and the heat in the exhaust air through the evaporator in winter. This not only improves the unit’s energy efficiency ratio, but also saves the unit’s defrosting process in winter.

Considering that the work of the linear accelerator will ionize the air, producing N, O, (nitrogen oxide) and O; (ozone). If the unit adopts the first heat recovery method, cross contamination between fresh air and exhaust air cannot be avoided. The second type of heat recovery device is also faced with a situation of low heat exchange efficiency and cannot maximize the use of energy in the exhaust air.

In summary, the third form is the heat recovery method that best meets the requirements of sanitation and energy saving. If you choose an integrated heat recovery fresh air unit, you should consider the permeability of the fresh air and exhaust air in the unit, and require the manufacturer to check the air tightness of the fresh air duct and the fresh air duct of the fresh air unit, and ensure that the polluted air is under negative pressure. Area, the fresh air is in a positive pressure area.

4. Case Analysis

Due to the large exhaust volume of the radiotherapy machine room, the exhaust heat recovery fresh air unit should be given priority when selecting the type of the fresh air unit. Because the project is a renovation project, due to the size of the computer room, the exhaust heat recovery fresh air unit cannot be used.

Take the air conditioning and ventilation design of a radiotherapy room in a hospital in Nanjing as an example.

Because the linear accelerator has a heat dissipation capacity of 7kW, the heat in summer is significantly increased compared with general office buildings. In comparison, the heat load in winter is significantly reduced due to the large heat generated by the equipment. The main contradiction of the air conditioning in the radiotherapy room is in summer. Analysis of design conditions. The calculated outdoor dry bulb temperature of air conditioning in Nanjing in summer t=34.8 C, and the calculated wet bulb temperature of outdoor air conditioning in summer ャ=28.1 C. From the enthalpy diagram we can see that the outdoor air enthalpy hw=91 kJ / kg, and the temperature of the radiotherapy room is controlled at 20~ 22C, relative humidity is not more than 60%. From the enthalpy diagram, we can see that the indoor air enthalpy h.=43~48 kJ / kg, the fresh air volume V=4100 m%h, then the fresh air is processed to the indoor state point of the cooling capacity Q=pV(hw-hn) / 3600, Therefore, the required refrigeration capacity of the fresh air unit Q=58.8~65.6 kW. However, when selecting the type of fresh air unit, special attention should be paid to the actual capacity of the selected unit to handle fresh air, especially the existing finalized direct evaporative cooling fresh air unit. According to the fresh air volume to be processed, the general direct evaporative cooling fresh air unit is selected according to the existing samples. Often the state after fresh air treatment cannot meet the indoor design air parameters. At this time, the indoor air conditioner needs to bear part of the fresh air load.

In summary, when using active fresh air, priority should be given to the use of exhaust air heat recovery fresh air units to achieve the goal of energy saving and emission reduction. A reasonable fresh air unit should be selected, and the state points that the fresh air can ultimately handle and the enclosure structure should be considered. Incoming heat, heat dissipation of radiotherapy equipment, personnel density, lighting and other factors determine the cooling capacity of the air-conditioning indoor unit, so as to provide a reasonable and scientific basis for the selection of air-conditioning equipment.

5. Conclusion

The ever-changing medical equipment requires HVAC designers to have the spirit of advancing with the times. When designing the air conditioning and ventilation of the hospital’s radiotherapy room, they should know the others, dare to innovate, consider all aspects of influencing factors, and determine a reasonable plan. Only then can design an air conditioning and ventilation system that meets the requirements of the corresponding medical equipment.

The exhaust air volume of the hospital’s radiotherapy machine room is very large, and the exhaust air heat recovery fresh air unit should be selected first. This can not only bring economic benefits to the owner, but also achieve the purpose of energy saving and emission reduction. When selecting the exhaust air heat recovery method, specific problems should be analyzed in detail, and the exhaust air heat recovery method that meets its requirements should be selected for different problems. The hospital radiotherapy room can adopt the method of recovering the cold / heat in the exhaust air through the condenser / evaporator To achieve exhaust air heat recovery, and to minimize cross-contamination between exhaust air and fresh air.

In order to prevent the radiation from leaking through the air duct when the radiotherapy room of the hospital is working, a certain length of lead plate should be used for outsourcing protection where the air duct, refrigerant pipe and condensate pipe pass through the protective wall. The ventilation system can also be simplified. After the accident, ventilation was combined into one.

In order to prevent the leakage and cross flow of pollutants during the operation of the radiotherapy room in the hospital, independent condensate pipelines, underground exhaust air, and air-tight protection and thermal insulation measures are adopted for the exhaust pipes in and out of the room.

-

High-Precision Solutions from Leading Sheet Metal Cutting Machine Manufacturers

2025/09/11 -

Reliable Sheet Metal Equipment for Sale to Support Precision Fabrication

2025/07/17 -

Advanced Duct Machine AC and Fabrication Solutions from Metmac

2025/07/12 -

The Advantages of Using a Sheet Roll Forming Machine in Manufacturing

2024/09/14

-

Precision and Performance: Advanced Sheet Metal Processing Solutions

2025/10/17 -

Advanced Sheet Metal Press, Shearing, and Forming Machines

2025/10/17 -

High-Performance Sheet Metal Laser Cutting Machines for Sale — Precision and Efficiency Combined

2025/10/17 -

Leading Sheet Metal Laser Cutting Machine Manufacturers for Precision Metal Processing

2025/10/17

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26