Understanding the Operation of Sheet Metal Forming Machines

- By:Metmac

- 2024-09-02

- 187

Understanding the Operation of Sheet Metal Forming Machines: Empowering Innovation in Manufacturing

In the realm of manufacturing, where precision engineering meets industrial ingenuity, sheet metal forming machines stand as veritable titans, shaping the contours of our world with their unmatched power and versatility. Understanding their intricate operation unlocks a treasure trove of possibilities for product innovation and manufacturing efficiency.

Mastering the Mechanics: A Symphony of Forces

Sheet metal forming machines employ a combination of fundamental mechanical principles to transform flat sheets of metal into complex shapes and components. These principles include:

Bending: Applying force to a sheet edge to create a bend, forming a desired angle.

Stamping: Using dies to punch or cut shapes out of a sheet, creating intricate patterns or holes.

Drawing: Stretching a sheet over a form, causing it to conform to a curved or angular shape.

Rolling: Passing a sheet between rollers to reduce its thickness or to create a rounded shape.

Types of Machines: Tailored to Specific Needs

The diverse range of sheet metal forming machines available cater to different manufacturing requirements. Some of the most common types include:

Press Brakes: Rigid machines that apply force to bend sheets using a punch and die.

Stamping Presses: High-speed machines that cut or punch shapes using precision dies.

Drawing Presses: Advanced machines that draw sheets into three-dimensional shapes using specialized dies.

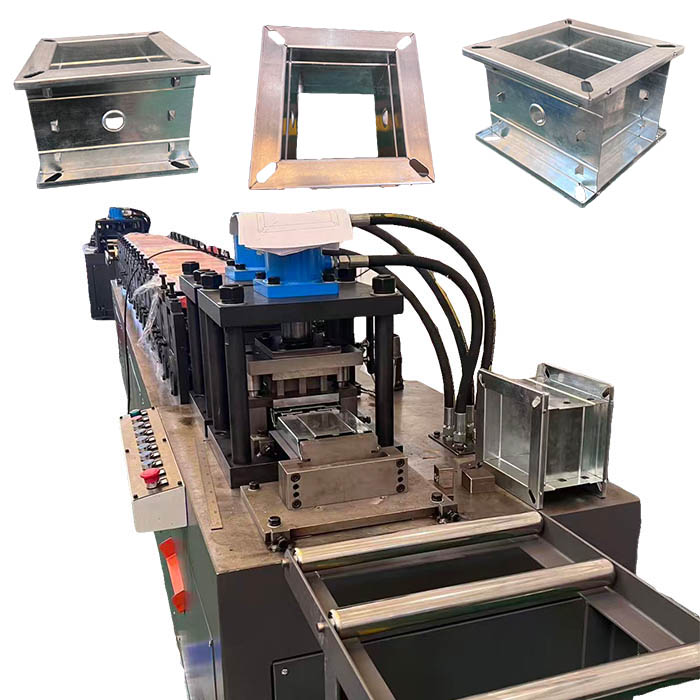

Roll Forming Machines: Continuous-feed machines that create long, curved or corrugated sections.

Control Systems: Precision at Your Fingertips

Modern sheet metal forming machines incorporate sophisticated control systems that provide precise control over the forming process. These systems include:

Computer Numerical Control (CNC): Computerized systems that automate machine movements based on digital commands.

Programmable Logic Controllers (PLCs): Microprocessors that execute user-defined programs to control machine functions.

Servo Motors: High-precision motors that ensure accurate positioning and repeatability.

Understanding the operation of sheet metal forming machines empowers manufacturers to:

Design and prototype complex parts with confidence

Streamline production processes and reduce costs

Enhance product quality and consistency

Innovate new solutions for various industries, from automotive to aerospace

-

Sheet Metal Machinery for Sale: Elevate Your Fabrication Capabilities with METMAC

2025/11/26 -

Laser Sheet Cutting Machine: Redefining Precision with METMAC Technology

2025/11/26 -

Sheet Shearing Machine: Achieving Unmatched Precision and Efficiency with METMAC

2025/11/26 -

Sheet Metal Forming Machine: The Art of Precision with METMAC Technology

2025/11/26

-

Advanced Sheet Metal Rolling, Laser Cutting, and Folding Machines for Precision Fabrication

2025/10/31 -

High-Performance Sheet Metal Bending and Cutting Machines for Modern Fabrication

2025/10/31 -

High-Quality Sheet Metal Equipment for Sale: Efficient Solutions for Modern Manufacturing

2025/10/31 -

High-Performance Sheet Metal Equipment for Sale: Forming and Shearing Solutions for Modern Fabrication

2025/10/22

-

Understanding the Role and Function of Steel Strip Slitting Machines

2024/05/11 -

Maintenance Tips for Longevity of HVAC Duct Machines

2024/05/11 -

Innovations in Steel Strip Slitting Machine Design and Technology

2024/05/11 -

Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

2024/05/11

-

A Guide to the Latest Innovations in Sheet Metal Folding Machines

2024/11/29 -

Key Features to Consider When Investing in a Sheet Metal Folding Machine

2024/11/28 -

Enhancing Precision with Advanced Sheet Metal Folding Machines

2024/11/27 -

How to Choose the Right Sheet Metal Folding Machine for Your Workshop

2024/11/26